Body Mounts Adjustable Height 4×4: Slash, Stampede

12,90 €

1 in stock

Quick Notes:

- Replaces stock Traxxas #6815R

- Fits either front or rear location on the Slash 4×4

- Fits the rear location on the Stampede 4×4

- Optional Front Shock Tower is also available

- Optional Rear Shock Tower is also available

RPM Adjustable Height Body Mounts for the Traxxas Slash 4×4 & Stampede 4×4 are designed to give you optional body height positions where stock left you none. Our version of the Slash 4×4 body mount starts off lower than stock by approx. 3.2mm. We supply a pair of molded spacers to allow you the option of a stock height body position using the thin spacer under the body mount. If monster suspension travel is needed or you just like the higher stance and larger wheel well openings a taller body mount provides, you can increase the height by 3mm using the thicker of the two spacers. In extreme cases, both spacers may be used for a full 6.35mm of extra body height.

We weren’t solely going for looks either. RPM body mounts are just plain tough! We engineered new, larger ribs into the mounts to provide extra rigidity and support for the body while keeping weight to a minimum. We mold these body mounts in black from our proven-tough blend of engineering-grade materials, which provides extra durability and impact-resistance in the most extreme situations.

What’s Included: Each kit contains two body posts, one body mount bracket, two spacers and two M3 x 16mm mounting screws. Two kits will be needed to complete one vehicle.

Tech Notes: RPM Body Mounts can be mounted in either the front or rear location on the Traxxas Slash 4×4. They only fit the rear location on the Stampede 4×4.

* Using both RPM spacers requires longer M3 x 20mm screws (not included).

| Weight | 0,025 kg |

|---|---|

| Dimensions | 140 × 80 × 20 mm |

Related products

Half shaft, external splined (steel-spline constant velocity) (1)

1 in stock (can be backordered)

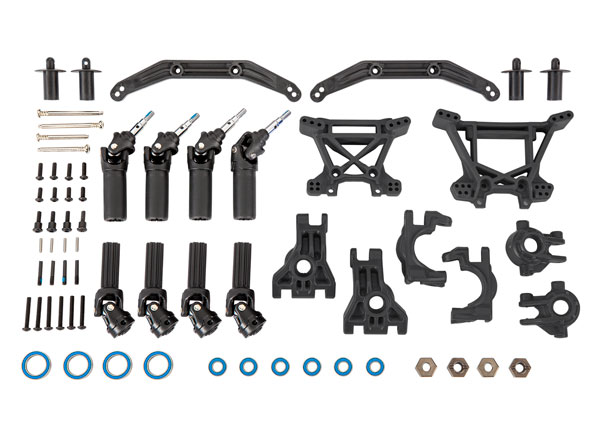

Outer Driveline & Suspension Upgrade Kit, extreme heavy duty, black

Available on backorder

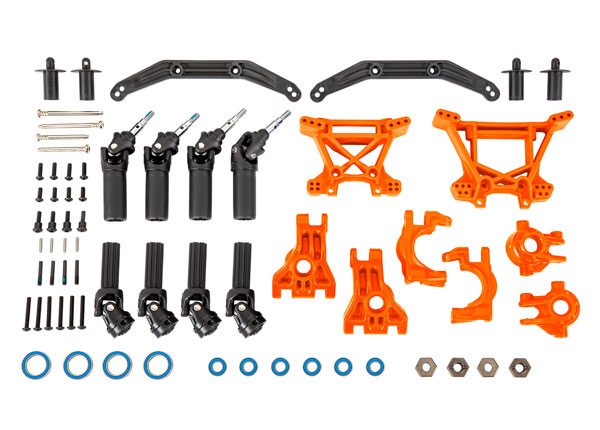

Outer Driveline & Suspension Upgrade Kit, extreme heavy duty, orange

Available on backorder

Stub axle, rear, 6mm, extreme heavy duty (for use with #9052R steel CV driveshafts)

1 in stock (can be backordered)